Introduction to the next generation of battery manufacturing

In the rapidly evolving world of energy storage, the emergence of printed batteries stands as a testament to innovation and forward-thinking. Spearheaded by the research and development at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM, this technology is setting a new standard in battery manufacturing. Moving beyond traditional methods, printed batteries offer a glimpse into a future where energy storage is more efficient, versatile, and environmentally friendly.

Innovations in battery manufacturing

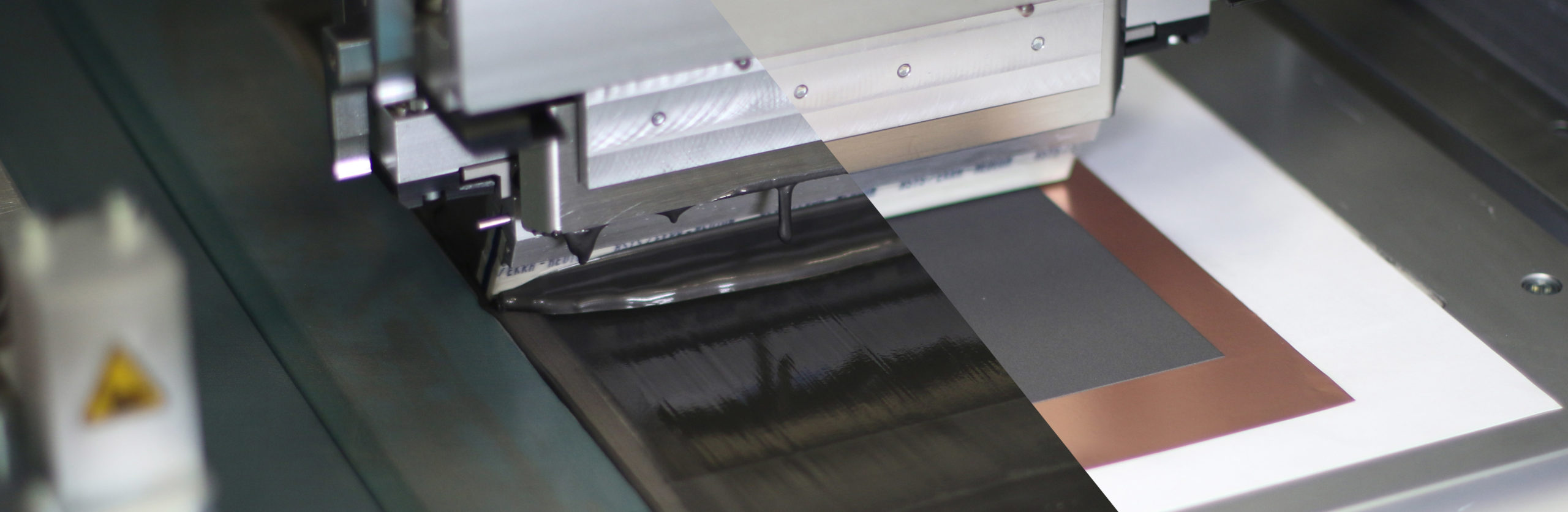

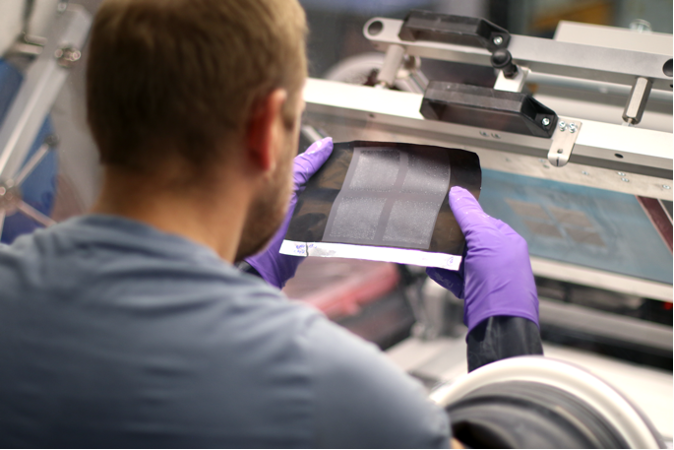

Fraunhofer IFAM is pioneering the use of screen printing processes for battery production. This technique offers significant advantages, including higher active material loads and greater freedom in electrode design. Printed batteries represent a leap forward, overcoming the limitations of traditional manufacturing methods and reducing the reliance on solvents and drying processes.

Printed batteries toward a greener future

In the quest for environmentally friendly energy storage, Fraunhofer IFAM focuses on increasing energy density and utilizing alternative, recyclable materials. Their research includes developing solid-state batteries using innovative screen printing techniques, which enable the production of thicker electrode layers for higher energy densities. This approach facilitates custom, on-demand battery production and promotes the use of nickel- or cobalt-free, water-based materials.

Bringing expertise into the field of additive manufacturing

Fraunhofer IFAM’s proficiency extends to the formulation and homogenization of printing pastes for electrodes. This process involves selecting suitable materials and optimizing the screen printing parameters based on the specific battery cell application, producing high-quality, thick electrode layers.

At Fraunhofer IFAM, creating batteries is like a mix of science and cooking. They carefully choose special ingredients – materials that store and conduct energy, binders that stick everything together, and even special additives to make the mix just right. It’s like making a special recipe for each type of battery.

Testing printed batteries for top performance

At Fraunhofer IFAM, testing printed batteries is like putting them through a fitness test. They build actual battery cells and then check how well they work. Think of it like testing how much energy the battery can hold, how long it can last, and how quickly it can power up.

The testing requires the use of special tools to measure things like the battery’s strength and endurance. It’s all about making sure that these new printed batteries are reliable and ready for action and replacing outdated technology! Great for both people and the planet.

The bright future of printed batteries

Printed batteries, especially ones like lithium-ion, are really important for storing energy both in things we carry and in bigger setups at home or work. Fraunhofer IFAM is working on making these batteries even better. They’re using printing techniques to make parts of the battery thicker to store more energy and designing them smartly to work more efficiently. Also, they’re cutting down on harmful chemicals, which is great for the planet. This new way of making batteries helps them perform better and opens up new possibilities for different shapes and sizes, fitting into all kinds of gadgets and energy solutions.

Leadership and application

Under Daniela Fenske and Mario Kohl’s guidance, Fraunhofer IFAM’s “Electrochemical Energy Storage” and “Functional Printing” teams are making significant strides in battery manufacturing using 2D and 3D printing processes. This work has broad applications, ranging from mobility and energy technology to life sciences and maritime technologies.

The development of printed batteries by Fraunhofer IFAM marks a significant milestone in battery technology. Their approach addresses current energy storage challenges and opens new avenues for sustainable and efficient energy solutions.

For more insights into this groundbreaking technology, visit Fraunhofer IFAM’s website and discover how printed batteries are shaping the future of energy storage.

Do you want to learn more about battery cell manufacturing and sustainable alternatives? No problem! Sign up for the battery training of the EBBC and dive deeper into the world of batteries!