EBBC at a glance: Explore now our free trial course along the entire battery value chain

Battery Cell Manufacturing

The second track gives a detailed overview of the entire process chain of battery cell manufacturing. Topics like material handling, paste production, the coating process, assembling, electrolyte filling and formation, next generation of batteries, green production and quality control will be discussed here. The track covers a workload of approx. 20 hours. The learning content is taught online on our learning platform. This allows you to work on the course content whenever and wherever you want and as often as you want without time pressure.

Topics:

- Introduction to battery cell manufacturing

- Topic 1: Materials handling for cell manufacturing

- Topic 2: Paste production

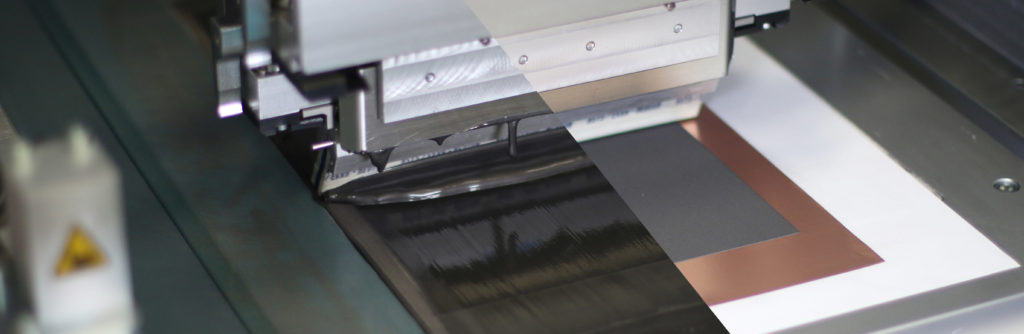

- Topic 3: Coating processes

- Topic 4: Assembling

- Topic 5: Electrolyte filling process

- Topic 6: Formation

- Topic 7: Next generation batteries

- Topic 8: Manufacturing technology for green batteries of the future

- Summary

Learning objectives

After the battery cell manufacturing module, participants will be able to:

Our experts

The experts in this module all come from Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM. Materials and process engineering aspects are in the foreground at Fraunhofer IFAM to develop solutions for electrical, chemical, and thermal energy storage systems. The focus is on Li-ion, solid-state, and metal/air batteries. Hydrogen and fuel cell technology as well as the efficient, highly dynamic storage of thermal energy represent further research areas.

Lithium-ion technology has dominated the development of electrochemical energy storage systems since the 1990s. However, other battery systems such as solid state batteries and metal-air batteries are also a particular focus at Fraunhofer IFAM. In the manufacture of battery cells, there are many interactions between the individual process steps, from the powder to the cell.

Changes to individual process steps therefore have an impact on the entire chain. Customized analysis techniques for material and cell characterization play an equally important role. Service life and battery aging can be specifically influenced by the choice of operating conditions. At the same time, safety must be ensured throughout the entire life cycle.

For research into next-generation batteries, a laboratory for the development of solid-state batteries is available at Fraunhofer IFAM in Bremen. The institute is also involved in the Fraunhofer Project Center for Energy Storage and Systems ZESS at the Braunschweig site. There, the research focus is on the fields of solid-state batteries and chemical hydrogen storage.

Hello, I am Daniela Fenske. I finalized my Ph.D. in Chemistry at the University of Oldenburg in 2009. In that year I joined the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM being part of the buildup of the energy storage labs and facilities from scratch.

My current position is Group Leader for new electrochemical technologies and cell diagnostics in the Energy Storage Department. The focus lays in the development of novel, sustainable battery technologies – from material to the cell and a digitization strategy for an efficient and sustainable use of battery data.

Since 2019 I am working as a project manager at Fraunhofer IFAM in Bremen. In the Electrical Energy Storage department, I work on the synthesis of innovative battery materials of the latest generation, their integration into electrochemical cells and the characterization of battery cells and modules.

Before that, I worked as a research assistant in the research group “Innovative Sensor and Functional Materials” at the University of Bremen from 2014 to 2018. From 2010 to 2014, I was a PhD student at the Interdisciplinary Center for Materials Science at the University of Halle/Wittenberg. My dissertation dealt with investigations on the morphology and composition of 0-3 composite dielectrics of novel capacitors for energy storage.

Before my doctorate, I completed my Master of Science Materials Science at the University of Leipzig. I also obtained my Bachelor of Science in Chemistry at the University of Leipzig.

Hello, I am Marcel Reisch, a Scientist and Project Manager at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM. My expertise lies at the intersection of scientific research and project leadership.

I completed my master’s degree at Fraunhofer IFAM, with the focus on Zink-Ion-Batteries. Specifically, my research has centred around the production and analysis of large-scale electrodes, with a particular focus on parameter identification for ensuring the long-term viability of scalable Zink-Ion-cell systems.

Since January 2022 I started my dual role as a scientist and project manager, where I actively lead research projects in the wide and dynamic field of electrical energy storage. I am practically involved in the development and production of the complete process chain of the battery production from the starting powder to the complete assembly of the cell on a laboratory scale up to the electrochemical analysis.